| Informacion Tecnica del Manufacturador (Se abre en otra ventana) | Walter |

| Insert Style | CCGT |

| Insert Size Code | 32.51 |

| Insert Shape | Diamond |

| Included Angle | 80 |

| Inscribed Circle (Decimal Inch) | 0.3750 |

| Corner Radius (Decimal Inch) | 0.0157 |

| Corner Radius (mm) | 0.40 |

| Insert Material | Carbide |

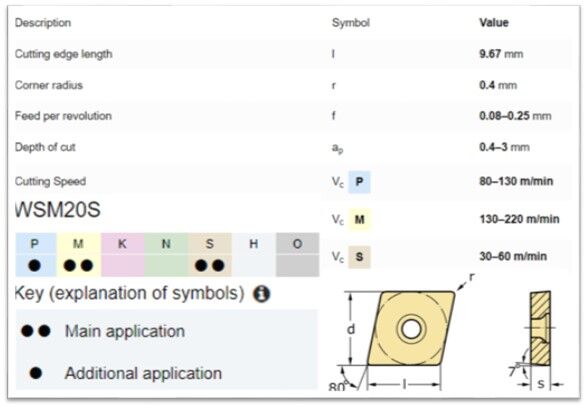

| Manufacturer Grade | WSM20S |

| Coating/Finish | TiCN; Al; Al2O3 |

| Relief Angle | 7 |

| Wiper Edge | No |

| Insert Thickness | 3.97 |

| Insert Thickness (Decimal Inch) | 0.1563 |

| Insert Hand | Neutral |

| Number Of Cutting Edges | 2 |

| Insert Shape Code | C |

| Corner Radius (Inch) | 1/64 |

| Hole Diameter (Mm) ( – 0 Decimals) | 4.40 |

| Hole Diameter (Decimal Inch) | 0.1730 |

| Maximum Depth of Cut (mm) | 9.67 |

| Maximum Depth of Cut (Decimal Inch) | 0.3810 |

| Inscribed Circle (Inch) | 3/8 |

| Inscribed Circle (mm) | 9.53 |

| Insert Holding Method | Screw |

| Insert Thickness (Inch) | 5/32 |

| Clearance Code | C |

| Tolerance Code | G |

| Series | CCGT-MM4 |

| Coating Process | PVD |

| Length Range (Decimal Inch) | 0.3000 – 0.4000 |

| Rake | Positive |

| Insert Length (Decimal Inch) | 0.3810 |

| Insert Length (mm) | 9.67 |

| Primary Workpiece Material | Stainless Steel; Superalloys & Titanium |

| Primary Workpiece Material Code | S; M |

| Secondary Workpiece Material | Steel |

| Secondary Workpiece Material Code | P |

| Iso Code | CCGT09T304-MM4 WSM20S |

| Standards | ISO; ANSI |

| Manufacturers Catalog Number | 6844578 |

| Material Grade | S20; M20; P20 |

| Proprietary Coating Designation | WSM20S |

| UNSPSC Code | 23242105 |

| Lead Angle | 80 |

| Coating Classification | PVD |

| Chip Breaker | MM4 |

| Rake Angle | 7 |

| Cutting Edge Style | Honed |

| Industry Standard Number | CCGT3(2.5)1-MM4 WSM20S |

| Width (Decimal Inch – 4 Decimals) | 0.381 |

| Width (mm – 2 Decimals) | 9.67 |

| Multi-Use Tool | Yes |

| Full Radius | No |

| Multi-Use Application | Facing; Turning; Boring |

6844578, 31197726, CCGT09T304, G7915717, 74538331, 8800219OLD, 87766663, TKT00082

Valoraciones

No hay valoraciones aún.